Our wide range of multi axis twin spindle Sliding Head automatic lathes offer flexibility from simple to complex turned parts in low to high volumes.

Due to our continuous improvement, we are able to utilise the very latest technologically advanced machinery. Our sliding head range allows us to machine multi axis components from 1mm up to 38mm bar diameter. All machines are fitted with high pressure coolant, twin spindles, multiple face and cross driven tooling and up to 9 programmable axis including B axis for “Angled holes . This eliminates secondary operations allowing us to offer “One Hit” machined and turned parts at highly competitive rates.

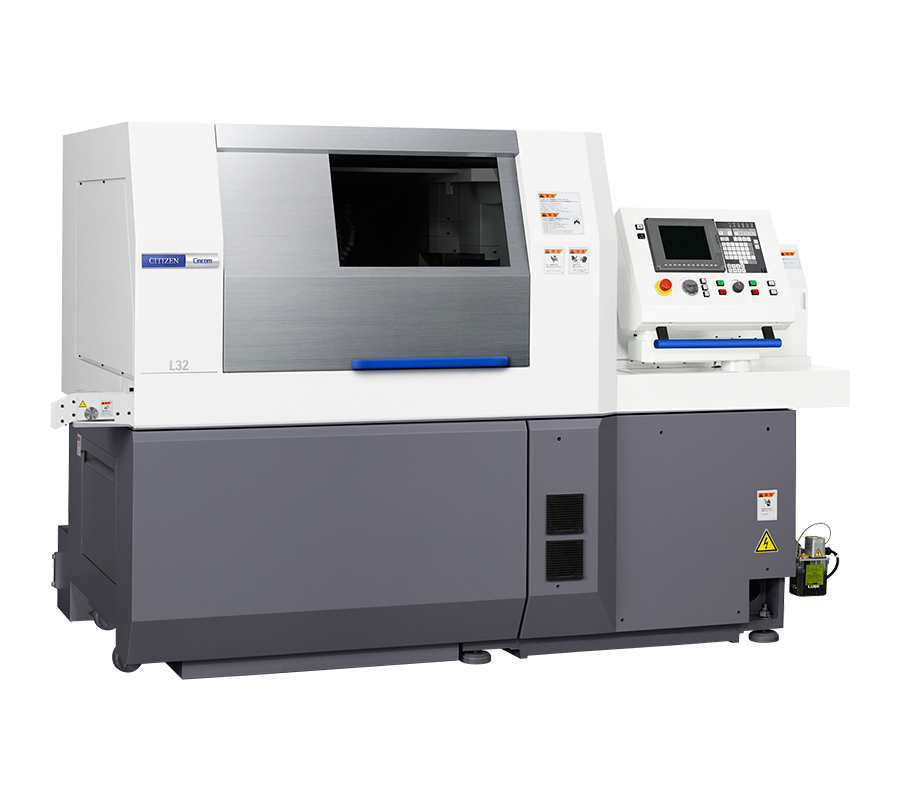

High volume production is embraced by utilizing the Iemca magazine bar feeders enabling continuity of production during un-manned shifts. We have been embracing the latest Low Frequency Vibration technology(LFV) with the L32 equipped with LFV, enabling us to control the swarf chips by programming an air cut to break the material into small pieces which extends too life and product yield rate. Quantities produced can vary from low volume into hundreds of thousands if required.

Size range ⌀1-38mm.